Reverse Engineering

Rebuilding old parts with a 3D Scanner’s help

TYPE EDIT can import 3D files such as STL, ASC, ISO… These file formats come from Renishaw® scanners or from most of the 3D Scanner on the market. Therefore a Cloud of points, that is to say a 3D file with XYZ coordinates information can easily be used or connected as a direct digitized 3D mesh. Then, that same object can directly be modified within TYPE ART module and rebuilt as previous Die machined inside TYPE CAM.

Remodeling the past and consequently insuring its future

Rebuild old broken and forgotten parts with Engineered tools

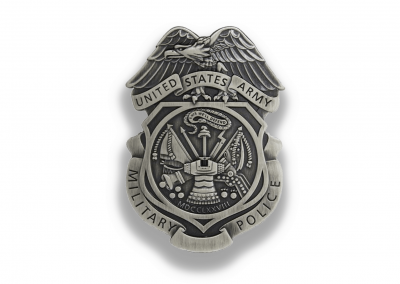

Reverse engineering is a crucial process by which usually a man-made part is deconstructed to reveal its designs, architecture, or structure. In other words this is the process to learn replicate an identical or even better designed object.

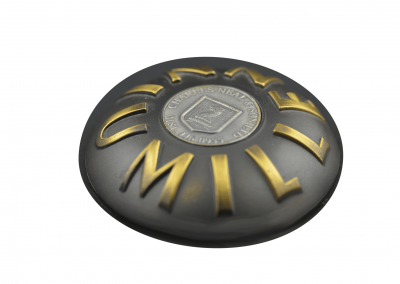

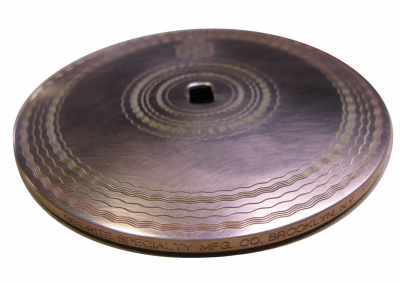

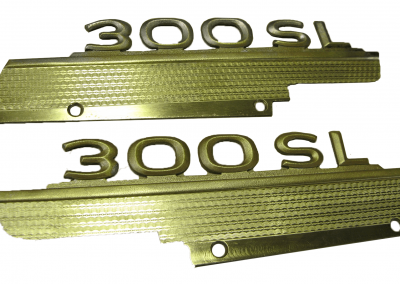

Reverse engineering is applicable in many fields of mechanical & manufacturing engineering, thank to the utilization of 3D Scanners for instance in the Coin Die industries. 3D scanning technologies and their real world applications keep getting more and more sophisticated as design-artistic industries demand more precise product data and enhanced precision. TYPE EDIT and TYPE ART modules are furnished of various tools helping to rebuild mold cavities or extracting perfect elements to be after that migrated into new ones.

Similarly, “Reverse Engineering” may also be used to create interoperable products. That is to say objects that can merged with others and allow portability to other third party CAD through a multitude of export formats. The objective being to create a working CAD design to enable CAM and unlimited production. A finished part is scanned using a 3D point cloud scanner. Then it is gradually formed into various mesh structures and again integrated into a CAD drawing, where it is further refined.

In conclusion, it may be modified for tolerances and finishes; ultimately it becomes a new design, ready for production and sometimes interactable with any other CAM software.

TYPE EDIT – Rebuilding a Die

Import & Alterations

With TYPE ART Module Users can draw contours lines and then easily transform them into 3D objects. With the help of many dedicated tools, the reconstruction of elements within a mold can be quickly set and therefore production restarted.

Various Reverse Engineered Parts built with TYPE EDIT

Want to know more about TYPE EDIT and its capabilities?

Contact us now to get in touch with a TYPE3 Representative.

Learn more about how to fulfill your customer’s designs with high level of details.